eco-Lab mixer

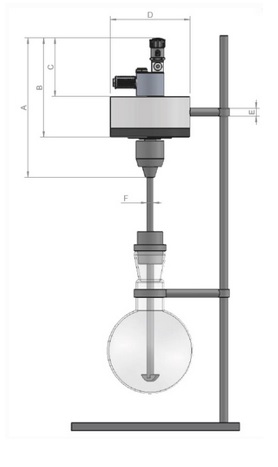

Our eco-Lab ATEX-Lab mixers were specially designed for a laboratory environment, for applications with support stands.

Characteristics:

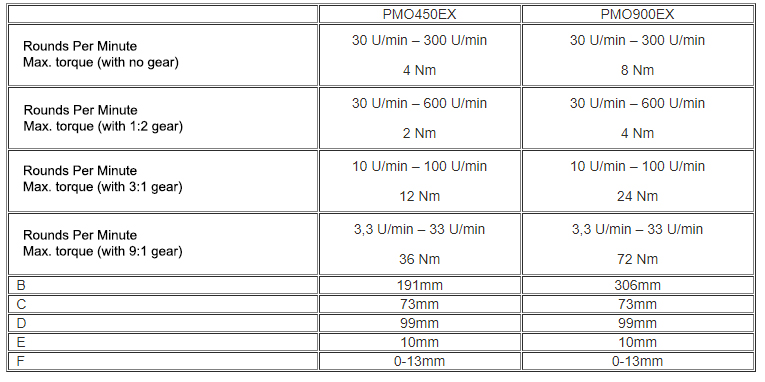

Our ATEX-laboratory mixer motors provide a complete solution for applications with support stands, with an ATEX license certified by TÜV Süd. Our laboratory mixers include motor and connection block, the holding chuck, fixing bolt, the mixing stem and mixing flaps. Thanks to the built-in fixing bolt, our eco-Lab mixers can be assembled simply and fast even onto a Radley reactor. Their control can be performed by simple Rounds Per Minute adjustment.

Thanks to the radial piston principle our laboratory mixers are extremely energy-efficient and have homogenous mixing characteristics.

- ATEX-license II 2 G/D c T5 100

- IP67 waterproof

- Hard cover aluminum casing with grounding

- Clockwise rotation direction

- Can be assembled onto a support stand

- Holding chuck for the mixing stem

- Oil-free drive

- Multiple sealing solutions (silicone-free, Viton, acetone-resistant)

- Mixer assembled on a support stand

- Chemical process tanks

- Processing of paints, varnishes, glues, filling and sealing materials

Accessories:

EX support stand

- Laboratory support stand with a 74 cm support rod

- With 2 cross fasteners

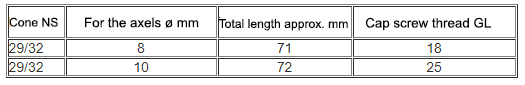

EX mixing flap connection

- Material: PTFE-EX

- Ambient temperature: -15°C – +200°C

- Chemical resistance: ++ very good

- Heat conductivity: 1,000 kOhm

Product description

The connection cone is made of static PTFE-EX material, and is equipped with rubber sealing rings to prevent the connection from slipping apart and to avoid the breaking of the glass. The special sealing made of PTFE EX material with the application of FKM sealing ring pressed down by a GL cap, provides excellent sealing. Grounding is ensured by an M5 threaded borehole.

Application

Perfect bearing for stainless steel, glass and mixer EX axels.

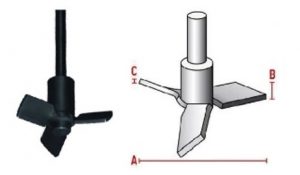

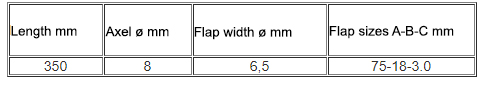

EX mixing flap

- Material: PTFE-EX

- Ambient temperature: -200°C – +250°C

- Chemical resistance: ++ very good

- Heat conductivity: 1,000 kOhm

Product description

The PTFE-EX stainless steel axel is made completely of PTFE-EX material and is equipped with three 45° angle rounded or square flaps. The component has good chemical resistance. The mixture only comes into contact with PTFE-EX material. The mixture moves from the bottom upwards, it is characterized by good axial flow and low force effects. The grounding may be performed, for example, with a sealing made of PTFE-EX material.

Offer request

Our colleague will contact you within 1 working day!

Magyar

Magyar