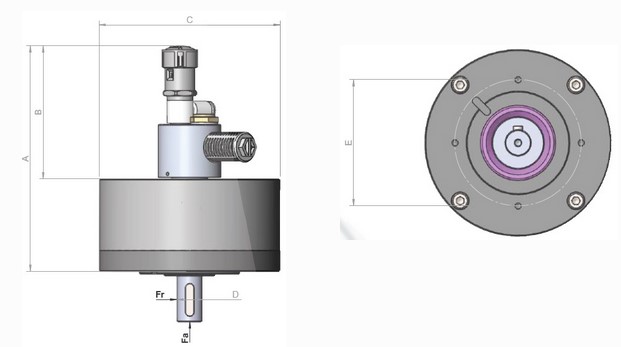

ATEX mixing motor

Our ATEX mixing motors equipped with connection blocks provide well-functioning and safe application in the ATEX environment.

Characteristics:

As a result of the energy-efficient radial piston principle, ATEX mixing motors make cost-efficient and consistent work processes possible. The built-in connection block combines an overpressure valve, a throttle-check valve and a silencer in a single compact component, for the purpose of safe and flawless motor connection and noise reduction.

- Connection block with an overpressure valve

- Throttle-check valve and Silencer → redundant overload protection

- ATEX-license II 2 G/D c T5 100

- Hard cover aluminum casing with grounding

- IP67 waterproof

- Clockwise rotation direction

- Oil-free and silicone-free

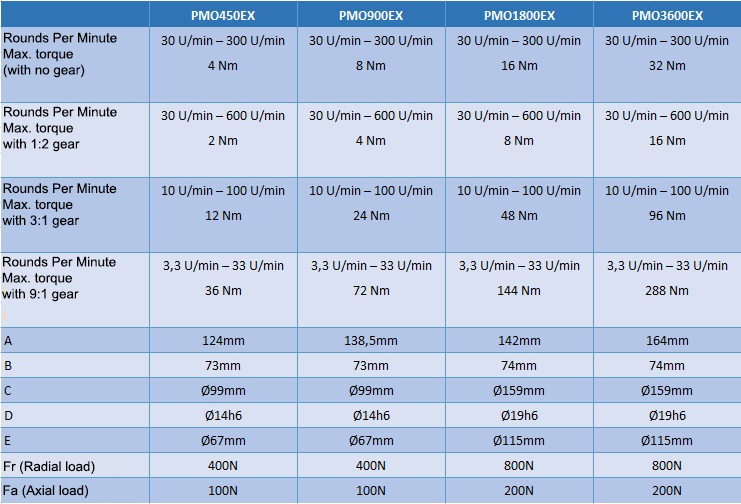

- 12 gears for precise Rounds Per Minute adjustment

- Memory function to prevent tilting

Areas of application:

- Mixers

- Varnishing technologies

- Chemical industry facilities

- Mills, grinding equipment

- Bulk material mixing

- Chemical process tanks

- Processing of paints, varnishes, glues, filling and sealing materials

Options:

- Assembly frame

- Counterclockwise rotation direction

- Prepared place for Rounds Per Minute sensor

Technical parameters:

As a result of the energy-efficient radial piston principle, ATEX mixing motors make cost-efficient and consistent work processes possible. The built-in connection block combines an overpressure valve, a throttle-check valve and a silencer in a single compact component, for the purpose of safe and flawless motor connection and noise reduction.

Offer request

Our colleague will contact you within 1 working day!

Magyar

Magyar