Eco-Mix Zone 1

The mixing motors of Eco-Mix combine the three most important characteristics of the mixing process in a single product: safety in ATEX Zone 1, energy-efficiency and homogeneous mixing quality.

Characteristics:

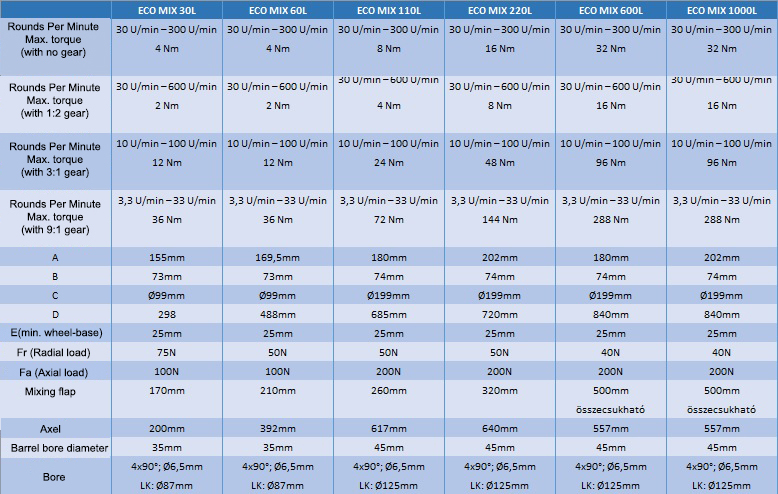

The mixing motors of Eco-Mix provide complete solutions, and ensure safety for standard barrel sizes (see the below Table) in ATEX Zone 1 (certified by TÜV Süd). The mixers that include a motor, connection block, bearing casing, axel and mixing flaps, provide a complete solution for standard size barrels. The motor of our Eco-Mix product is IP67 waterproof, which plays an important role in the easier cleaning of the motor, and how the motor behaves in relation to the fluids in the container.

With the optional Eco crossbar our Eco-Mix product can be simply assembled onto the open or closed container – ready and safe with no compromises.

Our mixing motors reliably consume extremely low amounts of air, which is the result of our radial piston principle PTM drive and has been perfect this way for several decades. In comparison with simple generic lamella mixing motors they consume 90% less air.

Of course, our Eco-Mix series provides oil-free and silicone-free drive as well.

- ATEX-License II 2 G/D c T5 100

- Needle valve to adjust Rounds Per Minute

- Hard cover aluminum casing with grounding

- IP67 waterproof

- Oil free drive

- Overload protection

- Coating technologies

- Chemical industry facilities

- Mills, grinding equipment

- Chemical process tanks

- Processing of paints, varnishes, glues, filling and sealing materials

Sizes and accessories:

Our Eco-Mix products provide complete solution for standard size barrels, with motor, connection block, rim, mixing stem and mixing flap that are fully harmonized with each other. Discover the world of Eco-Mix products based on our Table, and find the Eco-Mix product that is perfect for your barrel size:

Offer request

Our colleague will contact you within 1 working day!

Magyar

Magyar